Faithful to the tradition of continuous improvement of Forges Gorce, our design office continuously analyzes, improves and develops our ranges of flails, paddle blade, shackles, and other hammers. Thus, all our items are made from superior quality steels, adapted to the agricultural world. Our suppliers must comply with specifications specific to Forges Gorce in order to meet your expectations in terms of hardness, resistance to wear or the ability to absorb shocks during use in the field. Because we market our products only to trusted professionals, in more than 3000 agricultural or public works outlets spread across the world, we must always be the first. In this spirit of reliability loyal to our brand and in order to always better satisfy our customers, we have decided to expand our offer of feeler rollers and rotors.

Rotors, feeler rolls and spreader bearings : A complete offer

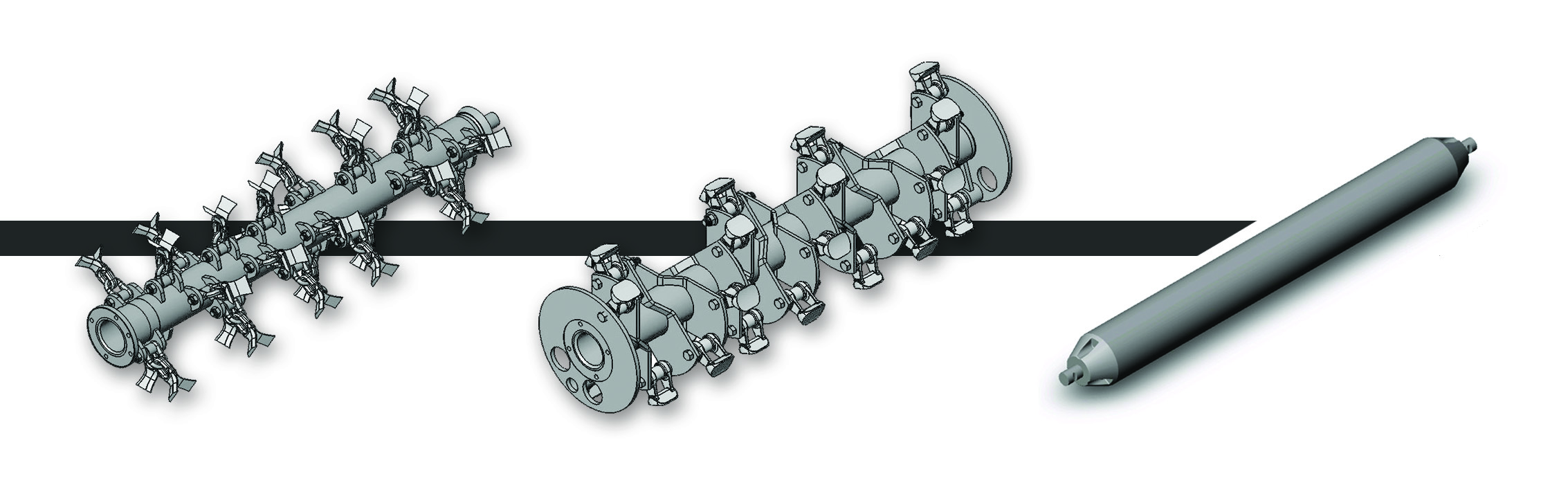

We now offer a wide choice of rotors adaptable to machines from major brands in the sector such as Rousseau, SMA, Noremat, McConnel, Bomford and CMV. The choice of an adaptable rotor is very important. When ordering, we kindly ask you to retrieve as much information as possible about your customer's machine : machine model, grinding group model, year, serial number, original reference, etc. These references will are generally supplied by the manufacturer upon delivery of the machine. You can now order high-quality, high-performance rotors and feeler rolls from Forges Gorce, which will help your customers perfectly carry out landscape maintenance and verge work.

_

R O T O R S F O R M O W I N G & B R U S H C U T T I N G

Our range of shackle rotors has been expanded and we now offer you adaptable products from Rousseau, SMA, Bomford and McConnel, with the same "manufacturer" quality. You will find rotors ranging from 0.80m to 2m, with or without bearing. We equip them with the famous Millennium type Y flails (FG000050), or paddle blade with twisted shackles and screws of Ø11 or Ø14 diameter according to your customer's wish and / or the technical characteristics of the original manufacturer. On estimate, we can also equip the rotors of the cutlery of your choice. About twenty references are kept in stock. We can therefore deliver to you within 48-72 hours.

_

Our forest rotors fit on Rousseau and SMA machines. In addition, you have two types of large wood rotors : flange rotors (exist with flanges 8mm or 12mm thick) and rotors called "squirrel cage". They are available in 1m or 1.20m and are equipped with our large forest hammers reference FG000502B. These have been reinforced thanks to the addition of material (+ 20%). They are therefore more resistant and offer a better quality of work as well as an increased longevity. You can also equip your rotor with carbide hammers made from 100% tungsten grain. This technology has been recognized and validated by many TP, agricultural and forestry users. The life of the hammer is multiplied X 3 !

_

The roller is also an essential element. It prevents direct contact with the ground and the tool, and it guides the orientation of the grinding group. New references have been added to the adaptable Rousseau and SMA range. We offer feeler rolls of different lengths (between 1m and 2.30m), as well as different tube diameters (between Ø101 and Ø168). Perfectly adaptable, they mount in place of your used and damaged original rollers on all your Agri and TP tools. We offer them with or without supports.

_

B E A R I N G S & S U P P O R T S

Several references of bearings and supports complete this range. We advise you to check the wear of your bearings when you change your rotor or probe roller. This ensures the life of your cutting tool, and reduces the vibrations of your machine.

How to maintain the performance of your machines ? Stones, logs and other objects in your work area can damage your rotor. It is therefore necessary to pay attention to warning signals such as vibrations or an imbalance which would entail a safety risk for drivers and users in the vicinity. The rotors have a lifespan of between 2000 and 3000 hours² approximately. We advise you to have it rebalanced at least 2 times during this period. Also don't forget your feeler roller which must be changed between 500 and 1500 hours² of work.

Our teams are there to repair, straighten and rebalance your rotors. With our balancing benches, we analyze your rotor and make the necessary corrections. Then we re-equip it with new Forges Gorce knives or hammers and renew the paint so that you get your rotor like new.Request your quote here

²According to working conditions.